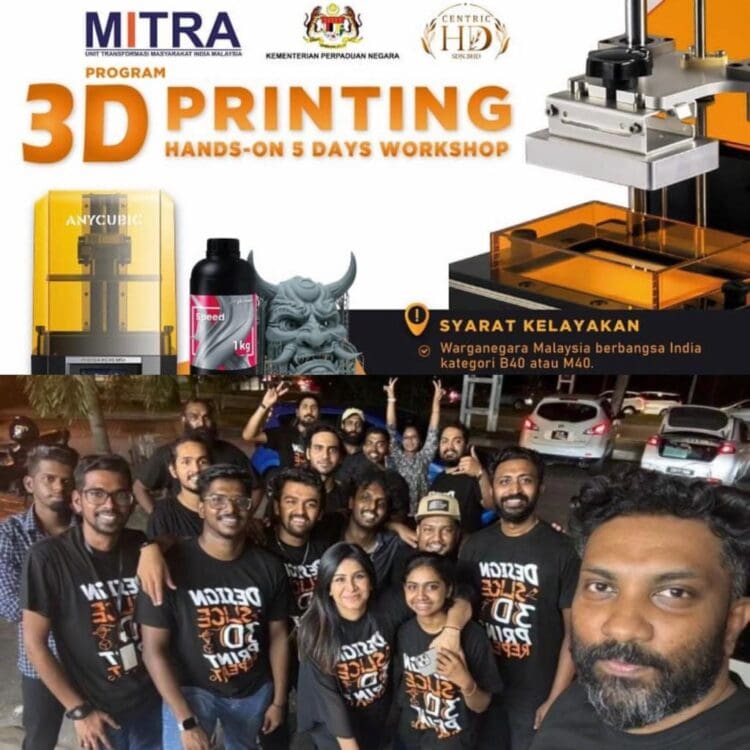

In the ever-changing world of technology, it is now critical to combine creativity with state-of-the-art tools. With our exploration of additive manufacturing, Mitra’s Program 3D Printing Workshop continues to be a source of practical education and skill building.

YB P. Prabakaran, the Chairman of Mitra and a Member of Parliament representing Batu Constituency, has honored the closing and certification ceremony of Mitra’s 5-day Printing Hands-On Workshop. April 8, 2024. fifty participants in all attended this life-changing 5-day workshop. YB P. Prabakaran awarded certificates of appreciation to each participant.As this groundbreaking 5-day course came to an end on April 8, 2024, a momentous occasion occurred, signifying a critical turning point in the path towards innovation.

This workshop organised by HD Sdn Bhd in collaboration with MMITRA JPM and under the guidance of Director JK Wicky, this workshop epitomized the essence of experiential education. Participants were immersed in a comprehensive curriculum designed to unravel the intricacies of 3D printing technology, from its fundamental principles to its practical applications across various industries said the programme organizer and Director JK Wicky.

“The 5-day workshop served as a catalyst for inspiration, exploration, and personal growth. By exposing participants to the endless possibilities of the 3D printing field, it aimed to equip them with the tools and confidence to become catalysts of change and pioneers of innovation in their respective fields and communities. By offering a structured yet immersive learning experience spanning five days, the workshop provided participants with the tools, knowledge, and practical skills needed to explore and harness the power of 3D printing technology,” said Wicky.

Key Learning from 5 days 3D Printing Workshop :

Participants gained hands-on experience setting up and operating Anycubic brand printers, mastering the installation and handling of 3D STL files for printing both small and over sized objects. They also learned essential skills such as cleaning, curing, and troubleshooting failed prints. Additionally, the workshop provided insights into advanced techniques such as airbrushing for coloring and dry brush style painting to enhance finished products.

To share the specific skills or techniques have participants acquired during the workshop, Wicky also added that “The airbrush technique offers a distinctive method for adding intricate details and vibrant colors to printed objects. Washing and curing printed objects require precise techniques to ensure optimal quality and durability. Moreover, printing objects in multiple parts and assembling them afterward demands careful planning and meticulous attention to detail for seamless integration and structural integrity.”

Overcoming Challenges with Creativity and Resolve

“Printing a 10 cm height object typically requires 4 to 5 hours, often extending into the night due to the slow process. To accommodate this, the workshop operates from 9 am to 5 pm, allowing printers to run overnight and produce results the following day. However, occasional failures may occur, necessitating reprinting to ensure successful outcomes,” Wicky uttered.

Key Learnings and Outcome of this 5days Workshop

Several students received inquiries for orders, showcasing their rapid grasp of the skills despite being first-timers in the class. Their ability to swiftly produce showcased objects on the final day, observed by guests, marked a notable achievement. Notably, an OKU boy participated and successfully produced results, highlighting inclusivity and individual accomplishment within the workshop.

Participants also nurtured and supported through WhatsApp mentoring, fostering collaboration and skill development. The overarching goal is to establish an in-house brand representing the collective talents of these students, specializing in 3D printed souvenirs and toy models for marketing purposes. Participants have the opportunity to craft personalized souvenirs, gifts, and collectibles, suitable for both personal use and sale. Moreover, they can design and develop prototypes, miniatures, and scaled models of innovative inventions, architectural wonders, and engineering marvels. This interactive learning experience extends to school environments, where students can readily acquire and apply this knowledge, fostering a culture of hands-on innovation and creativity.

Wicky also added that, “the giveaway printer proved to be a significant victory, granting students the ability to prolong their learning journey and engage in further experimentation. Their gratitude primarily centered around this invaluable tool. The passionate lecturers went above and beyond, sharing insights beyond the scheduled curriculum, which served as a profound eye-opener for all involved.”

He also said that they are planning to engage participants with disabilities (OKU), school teachers, and other targeted groups, we anticipate measuring the program’s impact with precision. These forthcoming initiatives aim to explore diverse perspectives and tailor the program to meet the unique needs of each participant demographic, ensuring a well-calculated and meaningful outcome.

Follow us on Instagram, Facebook or Telegram for more updates and breaking news.